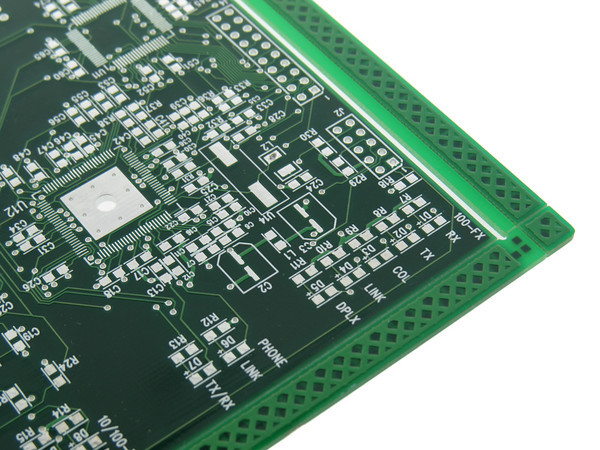

Lead Free PCBs

What is RoHS lead free PCB

RoHs (Restriction of Hazardous Substances Directive 2002/95/EC) is an environmental directive (but not a law) passed by the European Union in February 2003.

The basic principle of RoHs is that from July 1st, 2006, all electronic devices introduced into the market must not contain lead or certain other harmful substances. This applies to the following products:

Household appliances

IT and telecommunication equipment

Consumer electronics

Lighting devices

Electrical and electronic tools (except for large, stationary industrial devices)

Toys, recreational and sporting articles

Vending machines

Due to environmental issues, GoJGo provides service of manufacture printed circuit boards without lead for surface finish that requires rigorous concentration of 6 hazardous substances including Lead (Pb), Mercury (Hg), Cadmium (Cd), Hexavalent Chromium (CrVI), Polybrominated Biphenyls (PBB) and Polybrominated Diphenyl Ethers (PBDE). Among the 6 types of substances, lead is the most widely applied in the electronic plating. Therefore, lead-free is the best way for surface finish of PCB.

Attached our Certificate of RoHs.

The PCB surface finish can be chosen by customers. In addition to HASL lead free, the following lead-free solutions are also available for PCB:

Immersion Gold (ENIG)

Immersion Silver

Immersion Tin

Hard Gold

OSP

Surface treatment is a very important factor in circuit board production, which directly determines the quality of PCB. This involves HASL PCB and lead free HASL PCB . Lead is a toxic heavy metal, the human body to absorb excessive lead can cause poisoning, intake of low levels of lead could affect person’s intelligence, nervous system, the global electronic assemblies industry consumes about 60000 tons of solder every year, but also on the increase year by year, the resulting lead salt industrial dross serious environmental pollution, thus reducing the use of lead has become the focus of attention all over the world. GoJGo fully supports this practice. GoJGo’s lead free PCB manufacturing and lead free PCB assembly are fully compliant with RoHS standards, indicating that they are environmentally friendly and can be shipped to Europe and around the world.

Lead-Free PCB Materials and Process

The solder joint of HASL lead-free is 34℃ higher than that of with lead. Therefore, PCB manufacturers

have to make some changes in equipment, raw materials, technology, testing and other aspects to meet

the requirements of lead-free welding.

The key point of lead-free PCB is the selection of lead-free base material. We should study the heat

resistance, CAF resistance and machinability to choose the base material suitable for us and meeting

the requirements of lead-free.

The temperature required for lead-free soldering to reach solder joints has increased dramatically, it

is most important to use the base material with high decomposition temperature resin, or the heat

resistance of CCL mainly depends on the thermal decomposition temperature of the resin. Therefore, it

is not enough to only use the base material with high Tg and Z-CTE, which not only increases the

production cost but also can’t improve the heat resistance. IPC-4101c stipulates that the Td value of

lead-free base material should be greater than or equal to 325℃. GoJGo has carried out relevant

experiments. Under the same Tg and Z-CTE conditions, after the T260 test, the delamination time of the

base material with Td at 350℃ lags behind the base material with Td at 320℃ by 10s. Therefore, it is

better to choose the lead-free base material with Td value greater than 350℃ in actual production.

Only by increasing the thermal decomposition temperature of resin in CCL can the thermal reliability of

lead-free soldering PCB be guaranteed. The following is the commonly used material comparison table

used in GoJGo.

Lead-free base material have different machinability from with lead base material. For example, in laminating process, the Tg of lead-free base material will be higher, and the curing time will be longer. If the curing is not complete, the secondary curing will occur in the subsequent PCB processes and production, which will lead to serious expansion and shrinkage of the board size. In machining processes, the lead-free base material are harder and more brittle, GoJGo reduces tool rotation and cutting speed to prevent board splitting. In plug hole process, GoJGo will consider whether the heat resistance of plug hole ink is reliable, whether its Tg, CTE and other characteristics are suitable for lead-free base material, etc.

Lead Free PCB Assembly

At present, the lead-free development of passive components is progressing rapidly. In the global lead-free movement catalyzed by European Union laws and regulations, passive component suppliers leading semiconductor manufacturers to lead-free products. GoJGo provides comprehensive lead-free solutions. Our team is trained in all aspects of lead-free soldering, including solder tip selection, solder paste assessment, wave soldering assessment, process optimization, design principles, device assessment, reliability and equipment assessment, quality inspection and production cost. We have been actively implementing the transition to lead free products.

GoJGo always use the lead-free welding materials in production, such as solder paste for reflow soldering, tin bars for wave soldering, and tin wire for hand soldering. Lead-free soldering will be fully implemented. For some relatively expensive lead-free PCB parts, such as BGA, radiator parts, etc. GoJGo replaces the actual parts with non-functional “samples” to ensure correct reflow furnace temperature curves. Due to the metallic composition of lead-free solder, GoJGo trains inspectors to ensure that solder joints are of high quality and meet IPC-610D standards. Meanwhile, GoJGo also uses AOI, X_ray and other automatic equipment to find the soldering defects.

Normally, the customer will check the material in the BOM is lead-free or with lead. If you need help in checking whether the boards and materials meet the lead-free requirements, you can write us an email for getting suggestions. If you want to order, you can order by yourself online or email us.

Free PCB Request for Quotation (RFQ)

1. You can send email to us (tedchen163@yahoo.com). We will provide you with a

solution to make your PCB cost lower.

2. GoJGo receive your order,review the first,if there are questions,we will communicate with you

the first time and answer you about the lead time.

3. Our Engineering department will review this order with relevant departments,Produced in the best

process and in the shortest time.

4. Before shipment,we will talk with you about the shipping time and shipping method.

If you would like to customize your PCB type and place an order online, please click below to request a quotation.