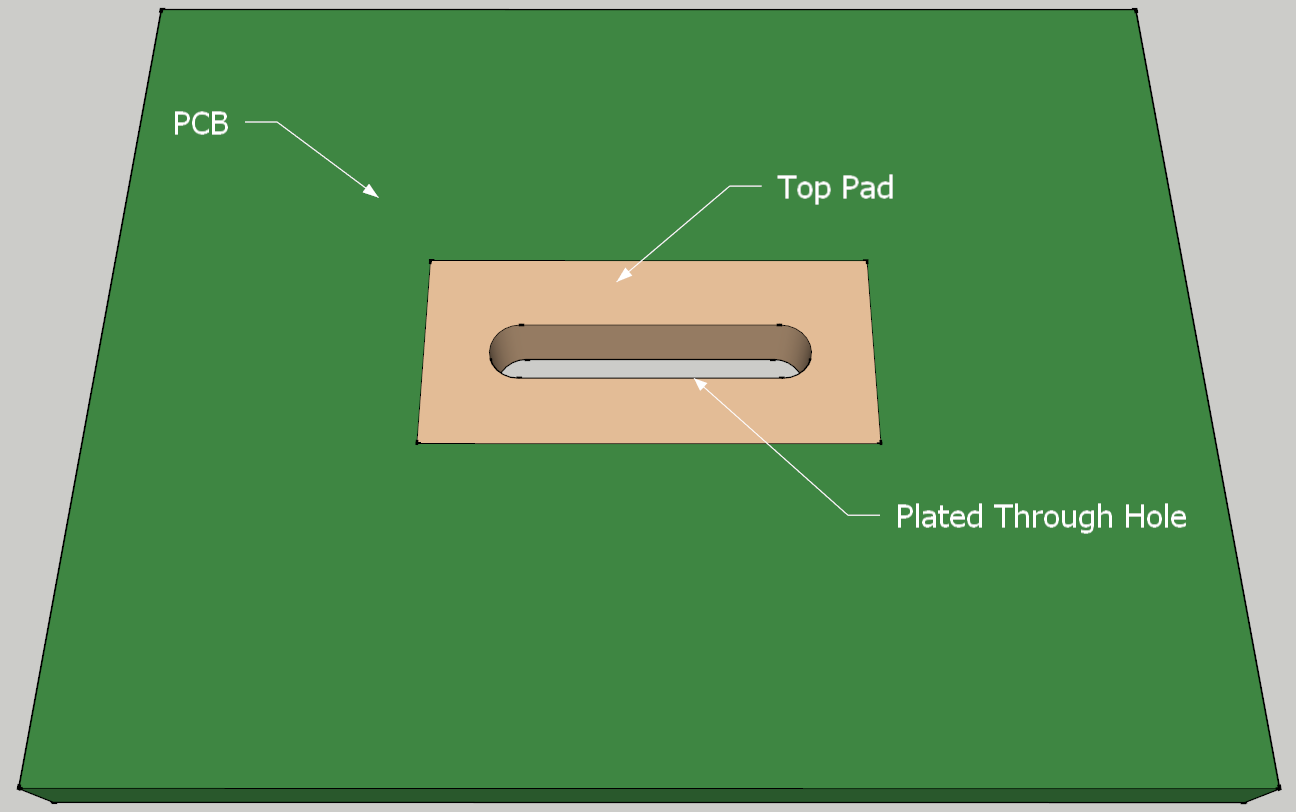

Usually for printed circuit board manufacturing, any annular slot of pcb board is using “milling process” rather than drill. The “milling tools” in diameter larger than “drilling tools”. Use the “milling tools” can quickly deal with any long annular slot or big drilling holes.

NOT use the “drilling tools” for any pcb annular slot is prevent drills tools damage.

DiGPCB’s manufacturer minimum annular slot distance: >= 0.8 mm, minimum drill size: >= 0.3mm (mass production)