Electronic test - probe test

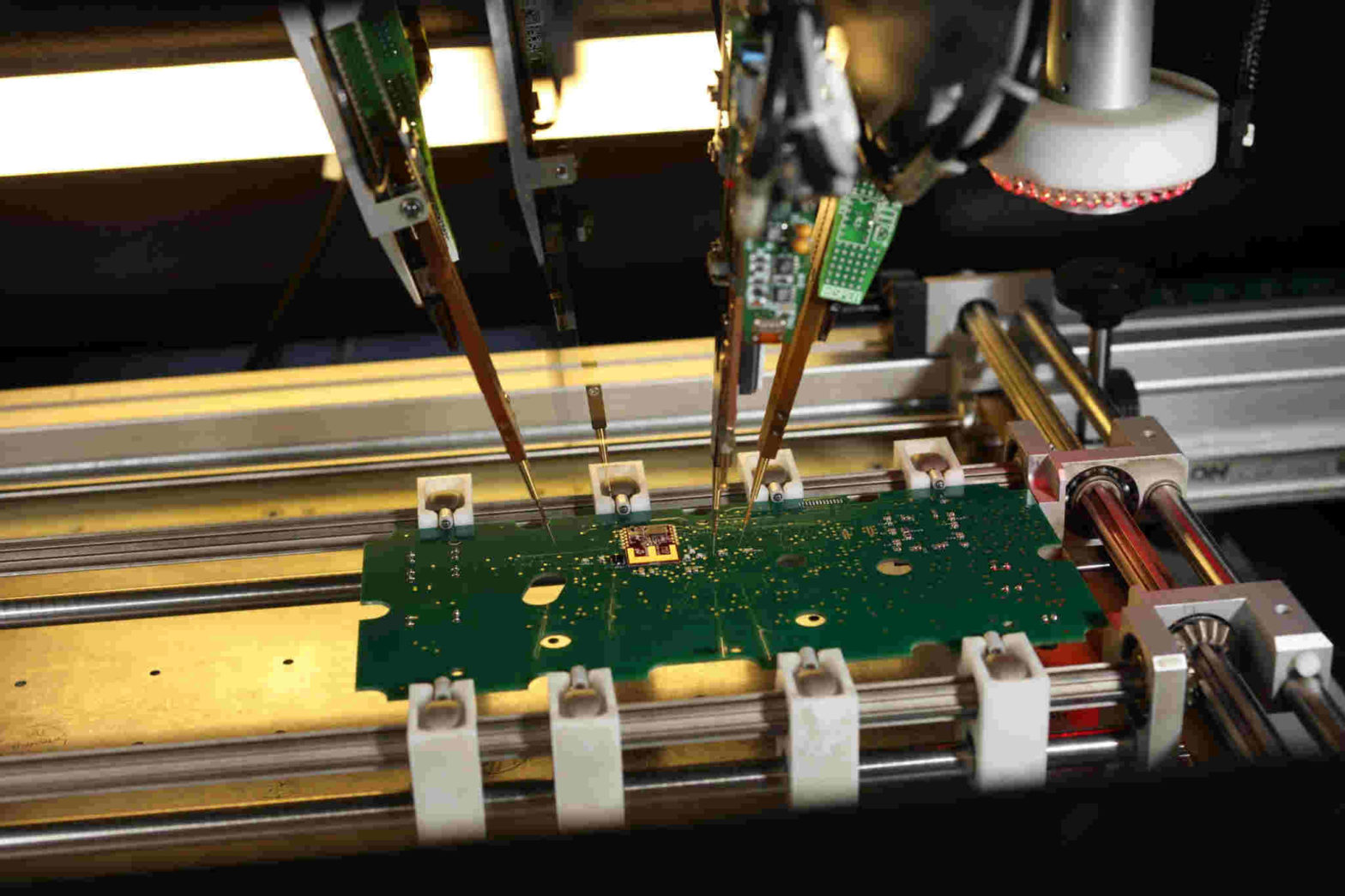

Combine Automatic optical alignment system and the traditional flying needle machine together,

with the help of image-processing software and flying-pin-only cameras, flying probe test is easier and more accurate.

The electronic test for circuit boards is performed after manufactured. All the PCB manufactured by PCBWay must be checked with flying probe test.

The layout is analysed according to the PCB file for short circuits and interruptions.This is important because only the E-test detects incorrect and broken conductors. And the detected defective circuit board will be rejected or marked.

It is a common mistake that a once free of errors produced circuit board no longer needs to be tested by the E-test. However, because each production batch of a circuit board is a one-time process, the E-Test has to be conducted each time.

E-test: flying probe or bed of nail?

Two types of equipment; flying probe and bed of nails can perform electrical tests on PCBs. In both cases, these tests are performed in our factory with the latest equipment.

The set up time of the flying probe method is fast, as it is basically only a software program that will suit the layout of your PCB. But the time required to test the PCBs is much longer as compared to a bed of nails. The obvious reason is that to test a board, the flying probes can only check one signal after the other.

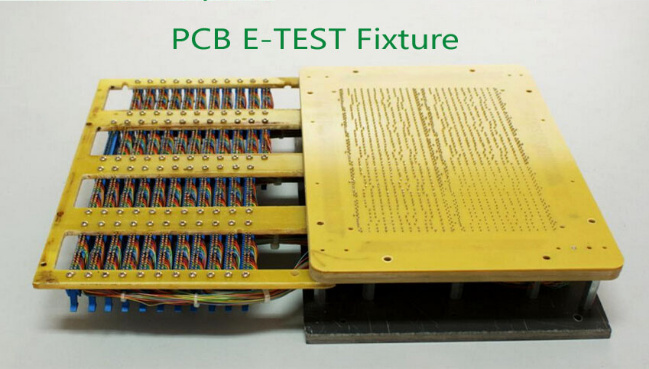

The other testing option is the ‘bed of nails’. In this situation, we are developing a specific jig for your board. As per the name suggests, the bed of nails is a surface on which multiple test probes are positioned in order to test all signals of the PCB panel in one single operation. It takes longer to build and cost more, as numerous probes are required to cover the full surface of the delivery panel. Yet, once the tester is made, the actual testing cycle will only take a couple of seconds to be completed.

In light of what has been described here above, the decision of writing a program or to build a hardware is basically related to volume (or to be more specific, to test points) per manufacturing batch.

We have defined this limit at 3 sqm (30sqft). Any batch smaller then this volume will be tested by the flying probe method. For any production batch above this volume, we will set up a bed of nail. In some situation, we even set up a fully automatic testing line with auto-feeder.

Bed of mail or flying probe, testing is an essential step in our procedure to ensure best quality to our customers. Regardless of the size of the batch, we confirm that 100% of our PCBs are tested before leaving the factory.

E-Electronic test for PCB is very important,Through E test, since there is only PCB PCB can be used 100%.

All PCB GoJGo manufacturing through the electronic testing before the final quality control.

Electronic test shortens the electrical test.

Electronic testing process to ensure that all the PCB before delivery to the customer without short circuit or open circuit,

How many kind of test method for Electronic test ?

There are two ways of PCB testing process

1. Flying probe test

By flying probe testing machine for testing.

Slowly flying probe test, and its test PCB connection network one by one.

A long time, generally cost 1-3 minutes.For 1 PCS.

Advantages

1.The cost is low

2. Don’t need to do a fixed testing tools

3. Low delivery time.

This type of PCB testing is use for small batch order on PCB prototype.

2. Fix tooling testing (bed of nail)

This test way means PCB are tested by Fixture testing machine.

Time is short for 1 PCS or panel,always in 5-10 sec.

But need to make a test fixture for each kind PCB.

It is not economical for PCB prototype,so, Fix tooling testing is suitable for mass production order. Pcb e-test fixture could be reused for repeat order.

Free PCB Request for Quotation (RFQ)

1. You can send email to us (tedchen163@yahoo.com). We will provide you with a

solution to make your PCB cost lower.

2. GoJGo receive your order,review the first,if there are questions,we will communicate with you

the first time and answer you about the lead time.

3. Our Engineering department will review this order with relevant departments,Produced in the best

process and in the shortest time.

4. Before shipment,we will talk with you about the shipping time and shipping method.

If you would like to customize your PCB type and place an order online, please click below to request a quotation.