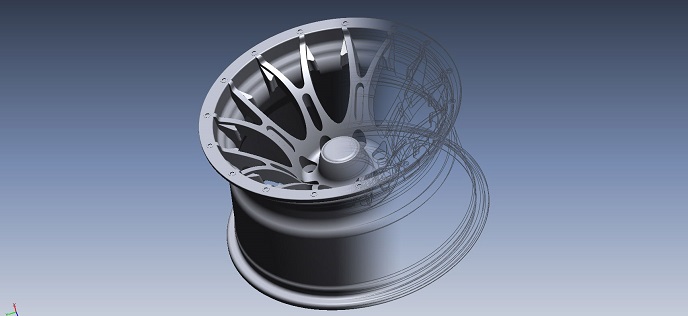

3D scan reverse engineering, 3D printing service

3D scanning is very important machining process in OEM industry, sometime our client only have the

physical products but no drawings, then 3D scanner will convert the physical objects into precise

digital models in computer. It’s enable you to quickly and accurately capture the details of product.

This process bring design engineer with a complete digital representation of part to be used for

reverse engineering, quality inspection or at any point of a typical manufacturing cycle.

3D scanning technology can provide customers with:

- Fast, ultra-accurate results, reducing your time to market (saving you time and money!)

- Complete measurement data of the entire surface of your object, verifying that the as-built part

matches your CAD model - True CAD models for FEA testing of actual geometry to correct problems before parts go into production

- CAD models to validate tooling, even when no current models exist

- Profile data of the whole part so assemblies can be digitally put together, revealing inaccuracies and

interference.

We can deliver in many native formats:

- AutoCAD

- SolidWorks

- Pro/E

- CATIA

- UG

- IDEAS

- Autodesk Inventor

- Rhino

- Revit

- CAE/CAM

- And others

Whether comparing a physical part to its CAD model or digitizing a prototype with the intent of developing a new CAD model, 3D scanning yields high accuracy point cloud data that can be modeled and used for:

- Tool path creation

- Polygonal / STL meshes

- Composite blends

- NURBS curves

- NURBS surfaces

- Tooling verification

- And many more

What is 3D Scanning?

3D Laser Scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a line of laser light. 3D laser scanners create “point clouds” of data from the surface of an object. In other words, 3D laser scanning is a way to capture a physical object’s exact size and shape into the computer world as a digital 3-dimensional representation.

3D laser scanners measure fine details and capture free-form shapes to quickly generate highly accurate point clouds. 3D laser scanning is ideally suited to the measurement and inspection of contoured surfaces and complex geometries which require massive amounts of data for their accurate description and where doing this is impractical with the use of traditional measurement methods or a touch probe.

The 3D Scanning Process:

Data Acquisition via 3D Laser Scanning

3D Laser Scanning Process An object that is to be laser scanned is placed on the bed of the digitizer. Specialized software drives the laser probe above the surface of the object. The laser probe projects a line of laser light onto the surface while 2 sensor cameras continuously record the changing distance and shape of the laser line in three dimensions (XYZ) as it sweeps along the object.

Resulting Data

The shape of the object appears as millions of points called a “point cloud” on the computer monitor as the laser moves around capturing the entire surface shape of the object. The process is very fast, gathering up to 750,000 points per second and very precise (to ±.0005″).

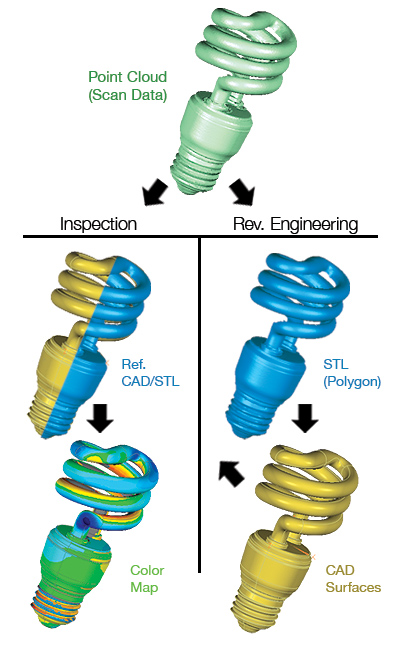

Modeling Choice Depends on Application

After the huge point cloud data files are created, they are registered and merged into one three-dimensional representation of the object and post-processed with various software packages suitable for a specific application.

Point Cloud Data for Inspection

If the data is to be used for inspection, the scanned object can be compared to the designer’s CAD nominal data. The result of this comparison process is delivered in the form of a “color map deviation report,” in PDF format, which pictorially describes the differences between the scan data and the CAD data.

CAD Model for Reverse Engineering

Laser scanning is the fastest, most accurate, and automated way to acquire 3D digital data for reverse engineering. Again, using specialized software, the point cloud data is used to create a 3D CAD model of the part’s geometry. The CAD model enables the precise reproduction of the scanned object, or the object can be modified in the CAD model to correct imperfections. Laser Design can provide a surface model or the more complex solid model, whichever results are needed for the application.

Free PCB Request for Quotation (RFQ)

1. You can send email to us (tedchen163@yahoo.com). We will provide you with a

solution to make your PCB cost lower.

2. GoJGo receive your order,review the first,if there are questions,we will communicate with you

the first time and answer you about the lead time.

3. Our Engineering department will review this order with relevant departments,Produced in the best

process and in the shortest time.

4. Before shipment,we will talk with you about the shipping time and shipping method.

If you would like to customize your PCB type and place an order online, please click below to request a quotation.